roughing end mill cutter diagram

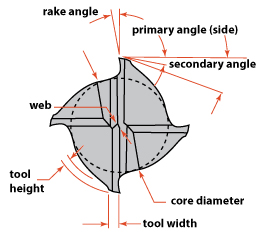

This is a flute diagram. Roughers have chip-breaker cutting edges the peaks.

How To Use A Milling Machine Instructions

HiTex-C 6 Flute Rougher.

. They are designed with cutting teeth on the face and edge of the body and can be used to cut a variety of materials in several directions. Roughing and finishing end mills4 Roughing End Mills. Up to 16 cash back Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

These cutters give a great performance under the toughest operating conditions. Roughing end mills are also sometimes known as rippa or ripper cutters. Download scientific diagram Two-flute end mill cutter geometry centre cutting type.

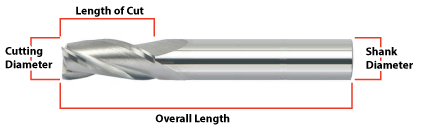

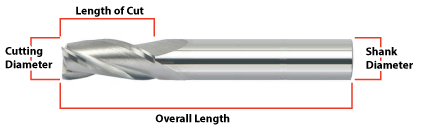

Roughing end mill diagram Saturday July 30 2022 Edit. Ad Browse discover thousands of brands. It is measured from the start of the necked portion to the bottom of the cutting end of the tool.

A wavy tooth is used from such cutters. Floating Tap Tool Holders. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep- pocket milling applications.

These cutters make very small chips that result in a rough. Find out more on the types of mills WOTEK offers and all the applications. Increased Core for Strength and Stability in Cut.

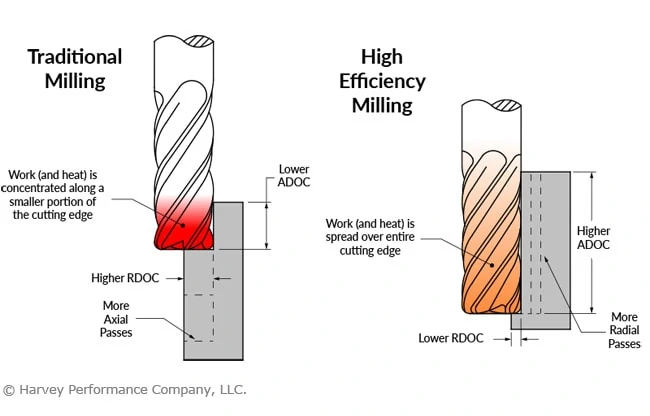

Fine Pitch Serrations for Chip and Form Control. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. High Temp Alloy Specific Geometry.

It is recommended to. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Ball nose cutters or ball end mills lower row in image are similar to slot drills but the end of the cutters are hemispherical.

Roughing mills are also known as Pippa cutters. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Roughing End Mills also known as ripping cutters or hoggers are designed to remove large amounts of metal quickly and more efficiently than standard end mills.

They are ideal for machining 3-dimensional contoured shapes in machining centres for example in moulds and dies. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Leave a rough finish but cut much faster than the finishing end mill.

Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Milling Cutters excluding end mills. This new catalog represents the results of our continuing commitment to our industry.

Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. Normally a 20 reduction in effective horsepower is used. Carbide Square End Mills.

The cutter may be a. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. As the names themselves suggest it is used to extract large amounts of material.

For over five decades Fastcut has specialized in the manufacture of quality end mills sold nationally through industrial distributors. End Mills are used for making shapes and holes in a workpiece during milling profiling contouring slotting counterboring drilling and reaming applications. Up to 16 cash back Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

Coarse tooth roughing end mills remove large chips for heavy cuts deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing application. It shows what a two flute three flute four flute six flute and eight flute mill end looks. Used for a variety.

These tools are designed specifically for aluminum although they are suitable for a very broad range of materials having up to high tensile strengths. Roughing End Milling Cutter. Founded in 1957 Fastcut Tool lives up to its name with Americas most extensive fast-cutting line of roughing end mills.

Roughing end mill Rough-cutters have notches or serrations on the cutting edge which like a mechanical shredder produces shorter easier-to-manage chips. Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco. Coarse-Pitch Roughing Aluminum CPRA CPRA series milling cutters are coarse-pitch HSSCo8 High-Speed Steel with 8 cobalt 3-flute 37 helix roughing end mills.

Read customer reviews find best sellers. The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools.

End Mill An Overview Sciencedirect Topics

Cutting Forces In End Milling Download Scientific Diagram

Flute Profile Of The End Mill Cutter Example 1 Download Scientific Diagram

Ball End Milling Cutter Geometry 16 Download Scientific Diagram

Two Flute End Mill Cutter Geometry Centre Cutting Type Download Scientific Diagram

End Mills With Diameter 20 Mm For Milling Experiments A End Mill With Download Scientific Diagram

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

End Mills Cad Cam Engineering Worldwide

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

The Secret Mechanics Of High Feed End Mills In The Loupe

End Mill An Overview Sciencedirect Topics

End Milling An Overview Sciencedirect Topics

Hss Roughing End Mills 5 16 3 4

End Milling An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co

Endmill Design Basics Mastercut Tool Corp

Endmill Design Basics Mastercut Tool Corp

8 Ways You Re Killing Your End Mill In The Loupe

Basic End Mills Technical Information Msc Industrial Supply Co